TZ 6500 - Commercial Grout Cleanup Machine

With a minimal amount of training, one laborer can do the work of 3 and do it three times faster! Water is changed less frequently so there is less down time. The TZ 6500 will clean 1,000 square feet per hour.

- NEW 2018 design

- Designed for large, open commercial areas

- Puts the operator in a comfortable, upright position

- Adjustable handle bars

- Our most powerful electric motor, for in/outdoor use

- Ridged steel construction for longer service life

- Additional sponge to floor pressure adjustments

- Rear solid casters; front solid, swivel casters

- Improved, dual access water bucket change

- Dual power rollers for more torque

- Cleans up to 1,500 sqft, per hour

- 14-inch-wide sponge belt

- Easy to clean and maintain

- Suitable for abrasive tile, quarry tile, glazed/unglazed ceramic, rough and polished natural stone

- Comes with a 1-year limited warranty

Electrically powered, the TZ 6500 uses a soft sponge belt which picks grout up off the floor surface, and is washed clean as it revolves around the rollers. Residue and water are pressed out in the attached bucket resulting in a clean, film-free surface. Only half the amount of water is required, unlike conventional methods, so grout joints are not washed out. Also, the operator works in an upright position, eliminating fatigue and stress on the knees and back.

The TZ 6500 is equally at home on brick pavers, abrasive tile, sure tread tile, glazed and unglazed ceramic, rough slate, natural stone, polished and unpolished marble & granite, and Mexican tile.

The TZ 6500 is powered by electric hand drills which are serviceable in the USA and Canada. Parts, including sponge belts (regular & epoxy), are available directly from TILE EZE INC. or any authorized TILE EZE INC. dealer. Constructed of galvanized steel with welded main frames, each model is virtually maintenance-free. Movable parts have sealed bearings for a smother operation, and belt replacement is quick.

Certain grouts may create excessive foam in the water bucket, making it necessary to change your water more often. To eliminate this problem, we recommend using the TILE EZE INC. Defoamer. One application of our defoamer will reduce excess foam.

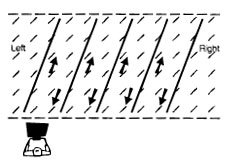

Read all enclosed directions completely before operating TZ 6500. We recommend practicing under controlled conditions before going to a job site to gain the techniques that ensure a professional job. The demonstration video included with the machine should be viewed before use. The TZ 6500 is designed to be used from left to right. Start the job on the left side and move stroke by stroke to the right to enhance the machine's performance.

Read all enclosed directions completely before operating TZ 6500. We recommend practicing under controlled conditions before going to a job site to gain the techniques that ensure a professional job. The demonstration video included with the machine should be viewed before use. The TZ 6500 is designed to be used from left to right. Start the job on the left side and move stroke by stroke to the right to enhance the machine's performance. 40190 Sprocket for Drill

40190 Sprocket for Drill Disconnect electrical supply.

Disconnect electrical supply.